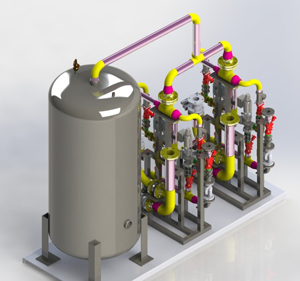

500 gallon NSF61 buffer tank with mixing station for use on conjunction with instantaneous hot water heaters.

Choice of copper, copper nickel and stainless .

Max output 300 USGPM

|

Plate and frame custom package for jacketted vessel . Combined pressure and temperature control with pump trap combination.

Inlet steam 100 psig

Outlet 12 psig

|

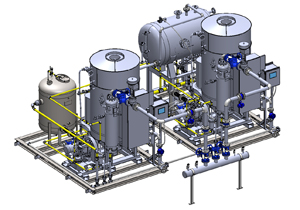

Plate and Frame custom package for process heating of hot water for production.

Electric control with high limit electric safety shut off.

Control panel integrated with central DCS/PLC

|

Custom duplex building heating package with plate and frame and pneumatic control valves.

Full hydronic package with VFD pump, expansion vessel and separator for building heating in Ontario Hospital

|

Condensate recovery for large industrial steam plant. A triplex steam powered pumping unit with back pressure control . The returned condensate was worth

$40 per hour so payback on the project was under 12 months with install including. Designed for outdoor use in a hazardous area the Nicholson P3 pump

Offer a spring free design and warranty for 3 m cycles. A viable alternative to electric pumps where power is not available |

Heat recovery skid for flash recovery and condensate recovery for production of hot water for food plant.

Estimated cost savings at $250,000 per annum

Payback 4 months

All stainless steel construction |

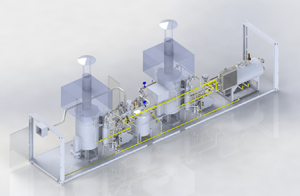

Fully packaged duplex boiler skid 150 HP 100 psig steam systems.

Skid included steam and gas metering and boiler efficiency panels.

Back pressure control and feedtank monitoring

|

Plate and shell hydronic package for building heating in major hospital.

60 HP VFD pumps with 1/3-2/3 temp control valves.

1200 USGPM units 100 psig steam |

Duplex 150 HP steam boilers in C Can for food processing facility.

Designed for 150 psig steam the plug and play unit enables switchover in 2 days.

Fully automated using Allen Bradley Plc.

|

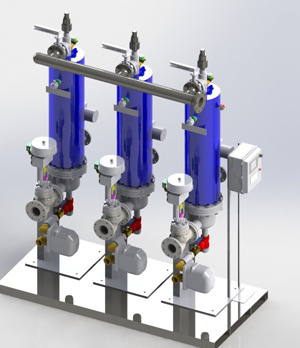

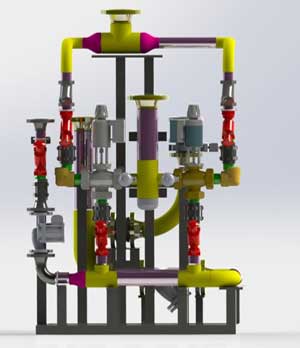

Custom made DHW triplex package designed to handle city water with hardness and PH value in-compatible with copper.

The unit was designed and constructed in 316 ss with HMI panel incorporating Bacnet MSTP and mixing station/buffer tank.

|

|

Duplex 180 USGPM mixing station to guarantee patient areas with hot water at 120 deg F.

Make up and system returns are handled in this mixing station.

Option of electric and pneumatic valves.

|